Isikhunta sesirinji esilahlwayo /isikhunta

Isikhunta sesirinji esilahlwayo singamathuluzi abalulekile asetshenziswa ekukhiqizeni amasirinji alahlwayo, asetshenziswa kakhulu ekujovweni nasekufakweni embonini yezokwelapha. Nazi ezinye izici ezibalulekile zokubunjwa kwesirinji esilahlwayo:

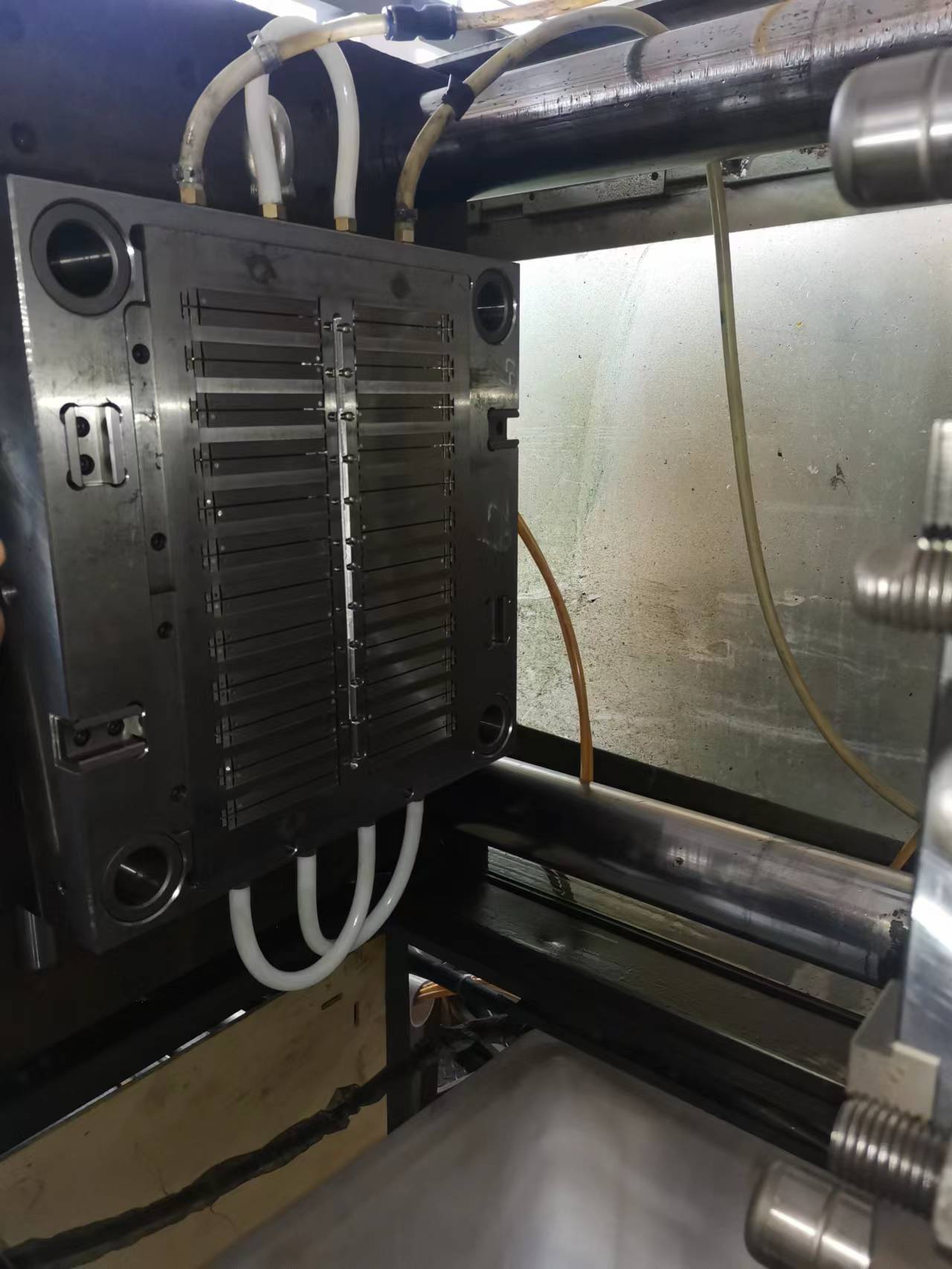

I-Mold Design: Isikhunta sesipetu esilahlwayo siklanyelwe ngokukhethekile ukudala umumo nezici ezidingekayo ekuhlanganisweni kwesirinji. Ngokujwayelekile, iqukethe ama-halves amabili, isikhunta somjovo kanye nesikhunta se-ejection, esihlanganiswa ukuze senze umgodi. Isikhunta ngokuvamile senziwe ngensimbi yekhwalithi ephezulu noma i-aluminium ukuze imelane nokucindezela okuphezulu nezinga lokushisa elihilelekile ekubumbeni umjovo.

I-Material Injection: Isikhunta silungiswa emshinini wokubumba umjovo ngokushisisa impahla eluhlaza (imvamisa ipulasitiki yezinga lezokwelapha njenge-polypropylene) ize ifinyelele esimweni esincibilikisiwe. Izinto ezincibilikisiwe zibe sezijovwa emgodini wesikhunta ngaphansi kwengcindezi ephezulu. Igeleza ngamashaneli namasango ngaphakathi kwesikhunta, igcwalise i-cavity futhi yenza ukuma komhlangano wesirinji. Inqubo yomjovo ilawulwa ngokuqinile ukuze kuqinisekiswe ukunemba nokuvumelana ekukhiqizeni isirinji.

Ukupholisa, ukuqinisa nokukhipha: Ngemva kokuba impahla isijovwe, insimbi encibilikisiwe iyaphola futhi iqine ngaphakathi kwesikhunta. Ukupholisa kungafinyelelwa ngamashaneli okupholisa ahlanganisiwe esikhunjeni noma ngokuhambisa isikhunta ekamelweni lokupholisa. Ngemuva kokuqina, isikhunta siyavulwa bese isipetu esiqediwe sikhishwa kusetshenziswa indlela efana nephinikhodi ye-ejector noma ukucindezela komoya ukuze kuqinisekiswe ukususwa okuphephile nokusebenza kahle esikhunjeni.

Izinyathelo zokulawula ikhwalithi zisetshenziswa kuyo yonke inqubo yokukhiqiza ukuze kuqinisekiswe ukuthi amasirinji ahlangabezana nezimfuneko ezidingekayo futhi athobela izindinganiso zezokwelapha. Lokhu kubandakanya ukuhlola imiklamo yesikhunta, ukuqapha imingcele yomjovo kanye nokuhlolwa kwangemuva kokukhiqizwa kwamasirinji aqediwe ukuze kuqinisekiswe ikhwalithi yawo, ukusebenza nokuphepha.

Sekukonke, isikhunta sesirinji esilahlwayo sivumela ukukhiqizwa okukhulu kwamasirinji alahlwayo, adlala indima ebalulekile ezindaweni zokunakekelwa kwempilo. Isikhunta siqinisekisa ukuthi amasirinji ahlala ekhiqizwa ngendlela edingekayo, ahlangabezana nezindinganiso zezokwelapha, futhi anikeze ukusebenza okuthembekile lapho esetshenziselwa umjovo noma ukumnika.

| 1.R&D | Sithola umdwebo wekhasimende we-3D noma isampula enezidingo zemininingwane |

| 2.Ukuxoxisana | Qinisekisa namaklayenti imininingwane mayelana: imbobo, umgijimi, ikhwalithi, intengo, impahla, isikhathi sokulethwa, into yokukhokha, njll. |

| 3.Faka i-oda | Ngokusho amaklayenti akho design noma ekhetha isiphakamiso design yethu. |

| 4. Isikhunta | Okokuqala Sithumela ukwakheka kwesikhunta ekuvunyweni kwekhasimende ngaphambi kokuthi Senze isikhunta bese siqala ukukhiqiza. |

| 5. Isampula | Uma isampula lokuqala liphuma linganelisekile ikhasimende, sishintsha isikhunta futhi kuze kube yilapho ukuhlangabezana namakhasimende egculisayo. |

| 6. Isikhathi sokulethwa | Izinsuku ezingama-35-45 |

| Igama Lomshini | Ubuningi (ama-pcs) | Izwe lokuqala |

| CNC | 5 | Japan/Taiwan |

| I-EDM | 6 | Japan/China |

| I-EDM (Isibuko) | 2 | Japan |

| Ukusika izintambo (ngokushesha) | 8 | China |

| Ukusika ucingo ( Maphakathi ) | 1 | China |

| Ukusika izintambo (kancane) | 3 | Japan |

| Ukugaya | 5 | China |

| Ukubhoboza | 10 | China |

| Lather | 3 | China |

| Ukugaya | 2 | China |