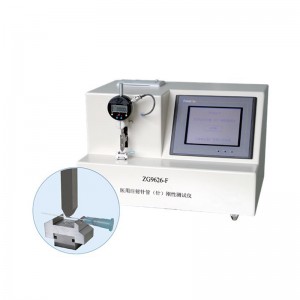

I-ZG9626-F Inalithi Yezokwelapha ( I-Tubing ) Isihloli Sokuqina

Umhloli wokuqina kwenaliti yezokwelapha iyithuluzi elikhethekile elisetshenziselwa ukukala ukuqina noma ukuqina kwezinaliti zezokwelapha. Idizayinelwe ukuhlola izici zokuguquguquka nokugoba kwezinaliti, ezingaba nomthelela ekusebenzeni kwazo phakathi nezinqubo zezokwelapha.Umhloli ngokuvamile uhlanganisa ukusetha lapho inaliti ibekwe khona kanye nesistimu yokulinganisa elinganisa ukuqina kwenaliti. Inaliti ivamise ukufakwa iqonde phezulu noma ivundlile, futhi amandla alawulwayo noma isisindo sisetshenziswa ukuze kuhoxiswe ukugoba.Ukuqina kwenaliti kungalinganiswa ngamayunithi ahlukahlukene, njenge-Newton/mm noma igram-force/mm. Umhloli unikeza izilinganiso ezinembile, okuvumela abakhiqizi ukuthi bahlole izici zomshini zezinaliti zezokwelapha ngokunembile.Izici ezibalulekile zomhloli wokuqina yenaliti yezokwelapha zingase zihlanganise:Ibanga Lomthwalo Olungisekayo: Umhloli kufanele akwazi ukusebenzisa inhlobonhlobo yamandla noma izisindo ukuze afake izinaliti ezinosayizi abahlukene futhi ahlole ukuguquguquka kwawo okunembayo kufanele kunikezwe ukunemba kwezilinganiso. inaliti, okuvumela ukuqhathanisa nokuhlaziya.Ukulawula Nokuqoqwa Kwedatha: Umhloli kufanele abe nezilawuli ezisebenziseka kalula zokusetha imingcele yokuhlola nokuthwebula idatha yokuhlola. Ingase futhi ifike nesofthiwe yokuhlaziya idatha kanye nokubika.Ukuthobelana Namazinga: Umhloli kufanele ahambisane nezindinganiso zemboni ezifanele, njenge-ISO 7863, ecacisa indlela yokuhlola yokunquma ukuqina kwezinalithi zezokwelapha.Izinyathelo Zokuphepha: Izindlela zokuphepha kufanele zibe sezikhona ukuze kuvinjelwe noma yikuphi ukulimala okungaba khona noma izingozi ngesikhathi sokuhlolwa.Sekukonke, ithuluzi lokuhlola elibalulekile lokuhlola isidingo sezokwelapha. izici kanye nekhwalithi yezinaliti zezokwelapha. Isiza abakhiqizi baqinisekise ukuthi izinaliti zabo zihlangabezana nezicaciso ezidingekayo zokuqina, ezingaba nomthelela ekusebenzeni kwabo nokunethezeka kwesiguli phakathi nezinqubo zezokwelapha.